Verander van taal :

Trillingsarme E4Q serie kabelrupsen in DMF 200|8 freesmachines

De DMG MORI-freesmachine is zeer nauwkeurig en wendbaar bij vijfassige simultane bewerking. Vijf assen bewegen gelijktijdig: drie lineaire assen in de XYZ-richtingen, een geïntegreerde draaikrans in het machinebed en de B-assen freeskop. De machine heeft freessnelheden tot 20.000 omwentelingen per minuut met maximale nauwkeurigheid en precisie (in het micrometerbereik). Het is dus belangrijk dat kabel- en slangleidingen geen trillingen veroorzaken. Daarom gebruikt de fabrikant kabelrupsen uit de E4Q serie van igus.

Gebruikte producten

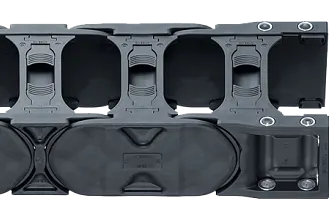

E4Q kabelrups

Gereedschaploos openen en sluiten van een kabelrups. Trillingsarm, onderhoudsvriendelijk en lichtgewicht.

Naar het product

readychain

Kant-en-klaar kabelrupssysteem: kabelrups, kabels, connectoren en accessoires worden volledig bekabeld geleverd.

Naar het productContacteer ons

Vragen? Neem dan contact op met:

Customer Service

Customer Service:

Telefonisch: Maandag tot vrijdag 8.00 - 17.00

LiveChat: Maandag tot vrijdag 8.00 - 17.00

Whatsapp: Maandag tot vrijdag 8.00 - 17.00

Plan een afspraak

Plan een afspraak met een expert